In crane operations, precision lifting is more than a performance goal—it’s a safety requirement. Every movement must be calculated, every load measured, and every risk minimized. Modern crane control systems make this possible, and one of the most vital components is the Greer A450832 Computer for Terex Cranes.

This advanced onboard computer works as the brain of the crane’s load moment system, giving operators the tools to lift with accuracy and confidence. It not only enhances safety but also helps extend the crane’s service life by preventing overloading and mechanical strain.

Why Precision Lifting Matters

In construction and heavy lifting projects, one mistake can lead to costly delays or worse, dangerous accidents. Precision lifting ensures:

- The load stays within safe operating limits.

- The crane maintains stability even in challenging conditions.

- Operators can work efficiently without second-guessing capacity.

With modern technology, such as the Greer A450832 Computer for Terex Cranes, operators can track load data in real time, reducing the risk of human error.

How the Greer A450832 Computer Improves Crane Control

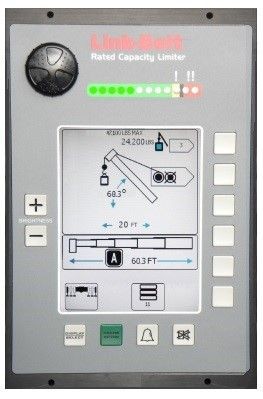

This computer integrates with the crane’s sensors, displaying critical information like:

- Load weight in real time.

- Boom length and angle for accurate positioning.

- Wind speed and environmental data for safe decision-making.

- Overload prevention alerts before limits are reached.

Its user-friendly interface and rugged design mean it performs well in demanding job-site conditions, from extreme heat to heavy dust exposure.

A Deeper Look at the Technology

The Greer A450832 Computer for Terex Cranes is more than just a display screen—it’s part of a complete load moment system. It works alongside hydraulic sensors, angle sensors, and wind speed indicators to give a complete picture of lifting safety.

Key technical advantages include:

- Real-time calculations to prevent overloading.

- Self-diagnostic capabilities to detect faults early.

- Compatibility with various Terex crane models.

- Durability in Class 1 Division 2 hazardous environments.

When a System Upgrade is the Right Move

Even with reliable computers like the A450832, older crane control systems may not meet today’s jobsite demands. That’s where upgrades, such as the Greer MG534 System Upgrade for Link-Belt Cranes, come into play.

An upgrade can provide:

- Faster processing for load calculations.

- More accurate sensors for boom and load monitoring.

- Improved operator interfaces for faster decision-making.

This kind of upgrade also ensures compliance with modern safety standards, keeping both operators and equipment protected.

Benefits Operators Can Expect

Using advanced crane computers provides real, measurable benefits:

- Enhanced safety: Constant monitoring of load and boom conditions.

- Increased productivity: Faster, more confident lifting decisions.

- Lower maintenance costs: Reduced stress on crane components.

- Regulatory compliance: Meeting or exceeding lifting safety guidelines.

These benefits are why operators and fleet managers consider such technology an essential investment rather than an optional upgrade.

Practical Use Cases on the Jobsite

On a windy day at a high-rise construction project, the A450832’s integrated wind speed monitoring warns the operator before unsafe lifting conditions occur.

During a heavy lift at a refinery, the system’s load limit alerts prevent the boom from exceeding its rated capacity. These safeguards don’t just protect equipment—they safeguard lives.

Maintenance and Calibration for Long-Term Performance

Like any precision instrument, the A450832 requires regular calibration and system checks. Best practices include:

- Annual calibration by certified technicians.

- Daily operator checks for display accuracy.

- Firmware updates for improved system stability.

When combined with professional maintenance, these practices keep crane operations smooth and predictable.

Future of Crane Control Technology

With IoT integration and AI-based predictive analytics on the horizon, future crane computers may analyze jobsite conditions before the operator even lifts a load. This could make tools like the Greer A450832 Computer for Terex Cranes even more indispensable in the coming years.

Key Takeaway

Crane safety and performance depend on accurate data, real-time monitoring, and reliable controls. The Greer A450832 Computer for Terex Cranes delivers all three, helping operators perform precision lifts with confidence. And for those seeking even more advanced capabilities, options like the Greer MG534 System Upgrade for Link-Belt Cranes bring modern efficiency to older machines.

In the world of heavy lifting, the right technology isn’t just a convenience, it’s a necessity.

FAQs

- What does the Greer A450832 Computer for Terex Cranes do?

The Greer A450832 Computer acts as the crane’s control hub, displaying real-time load, boom angle, wind speed, and other critical safety data to ensure precision lifting. - How does this computer improve crane safety?

It continuously monitors load limits and crane stability, providing overload prevention alerts and environmental warnings to reduce the risk of accidents. - Is the Greer A450832 Computer compatible with all Terex crane models?

It is compatible with various Terex crane models, but compatibility depends on the specific crane’s control system and configuration. Always confirm with a certified technician before installation. - How often should the Greer A450832 be calibrated?

Annual calibration by certified technicians is recommended, along with daily operator checks for display accuracy to maintain peak performance. - Can older crane systems be upgraded for better performance?

Yes. Upgrades like the Greer MG534 System Upgrade for Link-Belt Cranes offer faster processing, improved sensors, and modern safety features for older machines.